One of the most important things to consider and get right on a survival knife is the materials that the blade is made out of. There are so many different steels and materials out there to choose from, but not all of them will serve you well as the blade of a survival knife. After a lot of research and owning many survival knives over the years, here is my guide to the best blade materials for survival knives.

Survival knife blades need to be durable, resistant to wear, and have good edge retention. There are many different knife steel options out there for varying uses, but some of the best survival knife blade steels are D2, CPM S30V, and 1095. The blade material of a survival knife is very important.

The sheer amount of different steels and blade materials out this can be quite daunting. There are so many different options, and yet, a lot of them do not have the necessary qualities to make a really good survival knife blade. Choosing the best survival knife blade is one of the most important decisions to make for a new knife, and it is important to get it right. In this article I show you the best survival knife blade steels out there and what to look for.

Table of Contents

Best Survival Knife Blade Materials

If I attempted to list all of the knife blade steels out there in a single article, it would be a really LONG article. That’s why I have compiled this list of the top blade steel options for survival knives. By no means is this an extensive list, but from personal experience and a ton of research, these are going to work really well as a survival knife blade and will hold up through a lot of use and intensive tasks.

There’s really no such thing as the “perfect” or “best” survival knife blade steel because each steel serves a specific purpose and each has their strong points and their weak points. It’s really just about looking at the available options and choosing one based on what you deem important and will be the best fit for your needs.

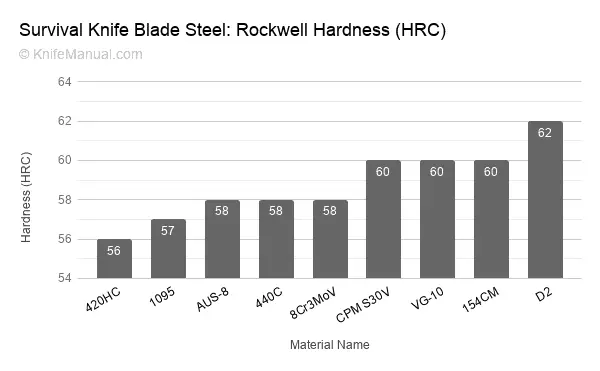

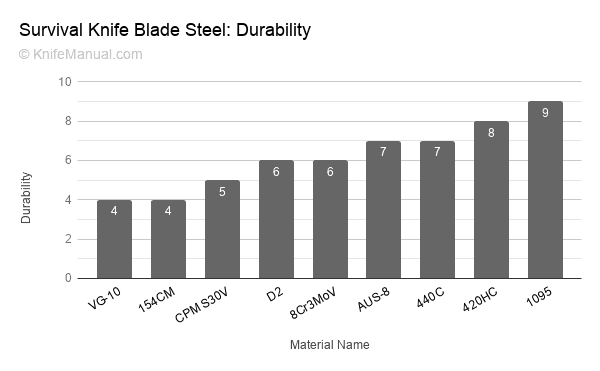

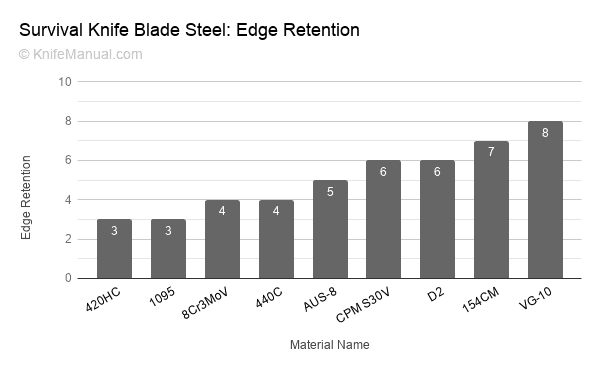

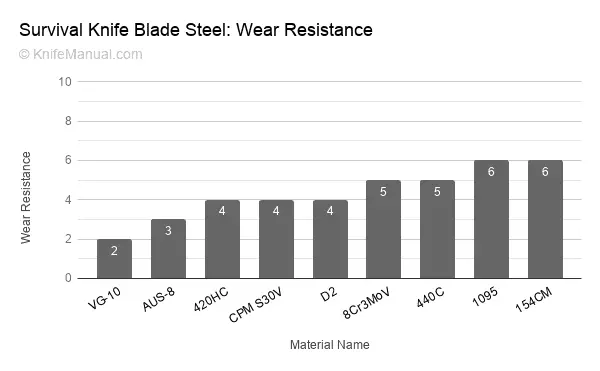

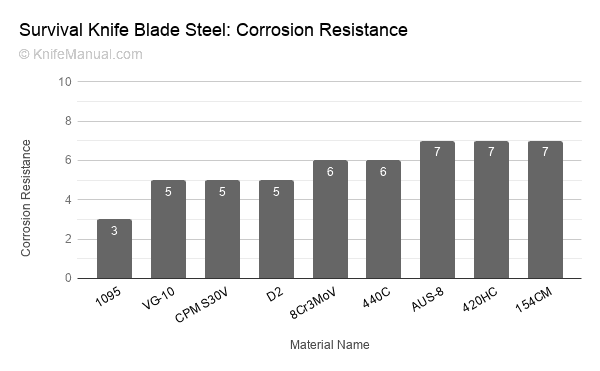

| Material Name | Rockwell Hardness (HRC) | Durability 10/10 | Edge Retention 10/10 | Wear Resistance 10/10 | Corrosion Resistance 10/10 |

| D2 | 62 | 6/10 | 8/10 | 4/10 | 5/10 |

| CPM S30V | 60 | 5/10 | 7/10 | 6/10 | 7/10 |

| VG-10 | 60 | 4/10 | 6/10 | 5/10 | 7/10 |

| 154CM | 60 | 4/10 | 6/10 | 5/10 | 5/10 |

| AUS-8 | 58 | 7/10 | 4/10 | 3/10 | 5/10 |

| 440C | 58 | 7/10 | 5/10 | 4/10 | 6/10 |

| 8Cr13MoV | 58 | 6/10 | 4/10 | 4/10 | 6/10 |

| 1095 | 57 | 9/10 | 3/10 | 6/10 | 3/10 |

| 420HC | 56 | 8/10 | 3/10 | 2/10 | 7/10 |

D2

| Material Name | Hardness (HRC) | Durability 10/10 | Edge Retention 10/10 | Wear Resistance 10/10 | Corrosion Resistance 10/10 |

| D2 | 62 | 6/10 | 8/10 | 4/10 | 5/10 |

One of my favorite knife steels for survival knives, D2 is just an all-around great option that holds up and does everything you could want it to. Overall, D2 is just a really great option for a survival knife and it can definitely hold up to the type of use that many survival knives are put through.

D2 has an exceptionally large amount of chromium in it, but not quite enough to classify it as stainless steel. It sort of skirts the edges of being stainless steel and carbon steel. While this might not seem that important, it actually has many upsides because a lot of the advantages of carbon steel and stainless steel combine in D2 and make it a really great knife steel.

Sometimes considered “semi-stainless” steel because of its large amount of chromium that almost makes it stainless steel, D2 has a lot of the qualities that you should look for in a survival knife blade steel. While not as tough as a lot of other tool steels, D2 is significantly tougher than stainless steel and is quite durable. D2 also has great wear resistance and holds an edge very well.

Some potential downsides to D2 are its ease of sharpening and its corrosion resistance. While the steel does a great job of holding an edge once it is sharpened, you might have some trouble sharpening it in the first place. The corrosion resistance, while not great with D2, is there but it definitely needs a good cleaning every so often and some oiling as well.

Some really great survival knives with D2 blades are the Ontario Rat II, and the ESEE Zancudo. Both are really great knives that are prime examples of what D2 blades look like and perform.

CPM S30V

| Material Name | Hardness (HRC) | Durability 10/10 | Edge Retention 10/10 | Wear Resistance 10/10 | Corrosion Resistance 10/10 |

| CPM S30V | 60 | 5/10 | 7/10 | 6/10 | 7/10 |

Often considered one of the best possible steels to make a knife blade out of, CPM S30V makes an amazing survival knife. CPM S30V is a really great survival knife blade option that will hold up to intensive use for sure and was intentionally designed to be really great knife steel.

The “30” in the name refers to the 3% vanadium in the alloy, but it also contains pretty large amounts of chromium and molybdenum. CPM S30V has excellent corrosion resistance that stops rust and other processes from happening quickly to the steel.

CPM S30V is very corrosion resistant, has good edge retention, and very resistant to wear. Overall, it is just a really great survival knife steel that will hold up and be able to withstand the harsh conditions and use that survival knives often have to endure. You can use this steel for some pretty hard tasks, and it will hold an edge pretty well and will show minimal wear.

While CPM S30V is overall a really great knife steel for survival knives, the one major downside to the steel is that it is difficult to sharpen. It does just fine holding an edge once it is sharped, but sharpening it is difficult and can be a real pain if you don’t know what you are doing.

There are a lot of really great survival knives with CPM S30V steel, but some of the best are the Gerber Gator and the Benchmade Saddle Mountain. Both of these knives are great for survival and are awesome examples of CPM S30V steel.

VG-10

| Material Name | Hardness (HRC) | Durability 10/10 | Edge Retention 10/10 | Wear Resistance 10/10 | Corrosion Resistance 10/10 |

| VG-10 | 60 | 4/10 | 6/10 | 5/10 | 7/10 |

VG-10 is a really great steel for a survival knife because it is high quality and has many of the attributes that you would want specifically for survival and for a knife that will be extensively used outdoors. It is very nice steel that makes great knife blades that you can really depend on and rely on.

With amounts of vanadium and chromium that make it tough and nicely resistant to corrosion, VG-10 is a really great survival knife steel. It is really important that a survival knife stays free of rust and corrosion, and VG-10 is like the perfect storm to combat that and make sure that it doesn’t occur and hold you back from doing tasks with your knife.

Originating from Japan, VG-10 has slowly made its way into the American market and around the world, because trusted and great knife makers like Spyderco, Fallkniven, and others recognized its potential and greatness and made some pretty sweet knives with the steel. VG-10 holds an edge pretty well and is resistant to corrosion and rust.

Overall, VG-10 is really great knife steel for survival knives and basically any other type of knife that is used a lot and needs to be durable and yet corrosion resistant. VG-10 is like the perfect combo of being able to hold an edge really well and still be reasonably tough and durable.

Many different knife makers have some really great VG-10 knives, but some of the best survival knives with this steel are the Spyderco Enuff and the Fallkniven S1. Both knives are really great and amazing examples of VG-10 in action.

154CM

| Material Name | Hardness (HRC) | Durability 10/10 | Edge Retention 10/10 | Wear Resistance 10/10 | Corrosion Resistance 10/10 |

| 154CM | 60 | 4/10 | 6/10 | 5/10 | 5/10 |

While some even go so far as to consider 154CM “super steel”, it is no doubt really great and high-quality steel. 154CM has a lot of great qualities that make it ideal for survival knife blades because it can stand up to a lot of intensive use, is corrosion resistant, and holds an edge pretty well.

154CM is often compared to 440C and ATS 34 steel but is considered slightly superior to them for many reasons. While all of the above steels are great and can make good survival knives, 154CM is considered better for a lot of small reasons that just add up to make it better knife steel. While 154CM has a slightly lower amount of chromium in it, it is still pretty corrosion resistant when compared to its most similar competitors.

There are just so many great aspects of 154CM, but some of the outstanding qualities of the steel are its blade durability and toughness, its edge retention, its corrosion resistance, and its ease of sharpening. All of these great qualities add up to make a really good and compelling steel that can make a pretty fine survival knife.

One last reason why 154CM is sometimes considered better than its closest competition is the fact that it is made by an American company. While a steel’s country of origin is really not a good indicator of quality, many people prefer American steel for whatever reason and this gives 154CM a slight edge over its competitors.

Overall, 154CM is a really great steel that has a lot of amazing qualities that make it a good survival knife blade. Some of the best examples of 154CM in action as a survival knife are on the Emerson Government Mule and the Ontario Black Bird SK-5. Both of these knives are really great survival tools and prime examples of 154CM steel as a knife blade.

AUS-8

| Material Name | Hardness (HRC) | Durability 10/10 | Edge Retention 10/10 | Wear Resistance 10/10 | Corrosion Resistance 10/10 |

| AUS-8 | 58 | 7/10 | 4/10 | 3/10 | 5/10 |

Made popular by knife companies such as Cold Steel, AUS-8 is a really great knife steel that has some really great qualities. While it does lack a little in wear resistance, AUS-8 is an overall great knife steel that is used in some pretty impressive survival knives.

This Japanese steel is just really great overall. It does, however, have an amount of chromium present that makes it sometimes difficult to sharpen. It also has a lower carbon content and doesn’t hold an edge as well as some more premium steels. But really, it is a really great steel and only begins to weaken when you compare it to really premium and expensive knife steels.

AUS-8 is a really tough steel that can definitely stand up to the task of being a survival knife blade. It also is really great because it holds an edge relatively well, is corrosion-resistant, and is easy to sharpen. It’s just really great steel that has some really great qualities that are absolutely necessary for a survival knife blade.

One of the best things, in my opinion, about AUS-8 is that it is relatively cheap and it still has some amazing qualities that can stand up to some of the more premium knife steels. Overall, all of its qualities, and its price, combine to make a really great knife steel that can work very well as a survival blade.

There are some really great knives with AUS-8 blades, but some of the best for survival purposes are the Ontario Rat I and the SOG SEAL Pup Elite. There are a lot more, including some great ones by Cold Steel, but the knives mentioned above are amazing and great examples of AUS-8 steel.

440C

| Material Name | Hardness (HRC) | Durability 10/10 | Edge Retention 10/10 | Wear Resistance 10/10 | Corrosion Resistance 10/10 |

| 440C | 58 | 7/10 | 5/10 | 4/10 | 6/10 |

440C as a survival blade is excellent because it exhibits some great characteristics that are perfect for outdoor intensive use. Often considered a pretty high-end steel, 440C has kind of been overshadowed by newer “super steels” but it still is a really solid option.

With a large amount of chromium, 440C is very durable and has pretty good corrosion resistance. 440C also holds an edge quite well and is just an overall good performing steel that is perfect for survival knives. The one place where 440C seems to lack is in wear resistance, although it is not all that terrible.

440C is a really common steel not only for its obvious great qualities but also because it is affordable. It is used in many mass-produced blades because it is nice and cheap, while also having a lot of the characteristics of higher-end blade steels. By no means does this make it less of a great survival knife blade material, in fact, it is really great for survival.

Overall, 440C is a really solid, all-around good blade steel choice for a survival knife. It holds an edge pretty well, is easy to sharpen, is durable, and is corrosion-resistant. Pretty good if you ask me because 440C is often pretty cheap and you can get a nice steel and overall knife for a bargain.

A lot of knives have 440C steel blades, but there are some that are better than others. Some of the best survival knives with 440C are the Boker Plus Ridgeback and the ESEE 4P-MB-SS. Both of these knives are just great and are perfect examples of 440C steel in action.

8Cr13MoV

| Material Name | Hardness (HRC) | Durability 10/10 | Edge Retention 10/10 | Wear Resistance 10/10 | Corrosion Resistance 10/10 |

| 8Cr13MoV | 58 | 6/10 | 4/10 | 4/10 | 6/10 |

Often compared to AUS-8, 8Cr13MoV is basically the Chinese equivalent. There are some differences though between the two steels such as 8Cr13MoV having a higher carbon content and being slightly more wear and corrosion-resistant. Either way, 8Cr13MoV is a great knife steel that works wonderfully as a survival knife blade.

It can be considered both a good thing and a bad thing, but 8Cr13MoV is a pretty cheap steel. While you will be missing out on a few qualities that come with premium and more expensive steels, 8Cr13MoV is affordable and has all of the necessary characteristics for a survival knife blade.

8Cr13MoV is great because it has good corrosion resistance and is very durable. While it could be better at keeping a sharp edge and its wear resistance, these qualities are adequate and it is overall a good blade steel option. For the price, 8Cr13MoV is amazing and it can do almost everything that you would need a survival knife blade to do.

There are many great and inexpensive survival knives with 8Cr13MoV blade steel, but some of the best are the Spyderco Byrd Cara Cara 2 and the Smith & Wesson M&P M2.0. Both of these knives are really great for survival and outdoor use and are great examples of 8Cr13MoV steel.

1095

| Material Name | Hardness (HRC) | Durability 10/10 | Edge Retention 10/10 | Wear Resistance 10/10 | Corrosion Resistance 10/10 |

| 1095 | 57 | 9/10 | 3/10 | 6/10 | 3/10 |

One of the most popular knife steels among survival knives, 1095 is just an all-around great steel that has most of the characteristics that you could ever want for a survival blade. Overall, this is just one of the best knife steels out there for survival knives, plus, it is often a lot cheaper than other steels that have many of the same characteristics.

Because 1095 is a plain carbon steel, it is susceptible to rusting and corrosion resistance pretty quickly. This is one of the big reserves why a lot of knife makers coat their 1095 blades with some sort of coating to try to delay the blade from corroding. Even with a protective covering on the steel, it will eventually corrode so it is always a good idea to keep it clean and oil it often.

While the lack of much corrosion resistance might make many people pass over this steel, it’s of the qualities that are almost too good to pass. 1095 is very durable, has great wear resistance, is easy to sharpen, and holds a pretty good edge. All of this combined to make one of the most popular and best knife steels for survival knives.

1095 steel is strange in the way that it is used in really bad and cheap knives, but also premium and really nice knives. What defines the differences between the two is really the heat treatment of the steel, as well as the knifemaker and their skill with the steel. Overall, 1095 is a really solid choice for a survival knife whether you pay a premium price for it or not.

There are just so many great survival knives with 1095 steel blades, but if I had to pick some of the best, they would be the ESEE Izula-II and the KA-BAR Becker BK2. It is really hard to choose favorites when there are so many great options, but both the knives above are really good survival knives and great examples of 1095 in action. Almost any 1095 ESEE survival knife is amazing as well.

420HC

| Material Name | Hardness (HRC) | Durability 10/10 | Edge Retention 10/10 | Wear Resistance 10/10 | Corrosion Resistance 10/10 |

| 420HC | 56 | 8/10 | 3/10 | 2/10 | 7/10 |

420HC is basically the high carbon version of 420 steel, and it really is a great improvement in regards to durability, edge retention, and basically every aspect of the steel. 420HC is one of the best 420 steel variations and has some pretty epic corrosion resistance

While it lacks a little edge retention and wear resistance, overall 420HC is an amazing steel for survival knives and knife blades in general. 420HC is a pretty inexpensive and lower quality steel when compared to premium steels, but competent knifemakers can really make some amazing blades with it.

420HC can be a little hard to sharpen because of its increased amount of carbon present, but it is a worthwhile sacrifice because its edge holding abilities improve greatly. You’ll usually find this steel on lower-end and less expensive knives because the steel itself is less expensive, but don’t let that fool you into thinking that this is lesser quality steel.

It’s hard to find a steel with better corrosion resistance and durability combined with adequate wear resistance and edge retention for the price. Overall, a very highly recommended steel that you should not let pass up because of its deceivingly low price.

While there are many good survival knives with 420HC steel blades, some of the best are the Buck 822 Sentry and the Gerber LMF II Infantry. Both of these knives are really great survival knives and good examples of 420HC steel in action.

Other Things to Consider About Survival Knife Blade Materials

After you have settled on a steel for your survival knife, there are a few more things to consider. While the steel that the blade is made out of is HUGELY important, there are other factors that determine just how good a knife steel is going to perform in the field.

Blade steel is sort of like the foundation of the blade and there are a few other processes and add ons that have to take place before the blade is totally finished. I’m not talking about the blade design or anything like that, I’m referring to the steel heat treatment and whether it has a coating/finish or not.

Heat Treatment

This is one aspect of a survival knife blade that cannot be ignored but is unfortunately looked over by many people buying a survival knife. You can have the best knife steel in the universe, but it if has a bad heat treatment, it will just not perform very well and you are probably better off getting cheap steel with good heat treatment.

Almost all major knife makers and anyone who knows slightly what they are doing will do a pretty good heat treatment to their knives, but it is always a good idea to check with them and find out the intricacies of their process to make sure that it is good and done thoroughly well.

Blade Finish

Depending on what blade steel your survival knife has, there may be an option to have a variety of different finishes to the blade. Finishes serve two main purposes: to protect or better the blade in some way, or just for aesthetics and beauty.

Not all survival knives need finishes, but you might choose to have one depending on your needs and preferences. If you do decide to have a finish on your knife blade, make sure it is done by a reputable knife maker so that it will last and be a quality finish.

Blade Coating

Blade coatings are like blade finishes, but instead of the blade being manipulated to look or act a certain way, coatings entail a coating of some other material around the knife blade to make it have the desired look or quality.

There are a variety of different coatings available, and, like blade finishes, the two main purposes of a blade coating are for extra functionality or for aesthetics. Not all survival knives should have blade coatings, if you decide to have one, make sure it is done well and is done properly or it will chip and scrape off easily when you are outdoors.

Stainless Steel or Carbon Steel for a Survival Knife?

There are a lot of different steels out there that you can choose from to have your survival knife blade made out of, but out of all of the available options, the two main contenders are carbon and stainless steel.

There is really no answer to which one is better for survival knife blades because they both serve different purposes and are good for different things. So it really depends on what you plan to do with your survival knife, what you value in a knife blade, and our preferences.

Stainless Steel

Stainless steel is really a really great option if you don’t want to have to do a lot of maintenance to your knife blade but still want a dependable and functional knife steel. It is very durable, tough, corrosion-resistant, low maintenance, and basically a really good option for a survival knife.

Some people don’t like stainless steel for a survival knife blade because it is harder to sharpen and doesn’t hold an edge as long as carbon steel, but it is a small difference and it would make sense to go with stainless steel if you don’t want to worry about rust on your blade. Overall, it is a really great option for a survival knife but there are a few tradeoffs.

| Benefits of Stainless Steel |

| Corrosion-Resistant |

| Low-Maintenance |

| Good for Striking a Firesteel |

| Very Durable and Tough |

| Makes for a Great Survival Knife |

| Drawbacks of Stainless Steel |

| Generally More Expensive |

| Harder to Sharpen |

| Doesn’t Hold an Edge for Long |

Carbon Steel

Usually a little bit cheaper than stainless steel, carbon steel is a great option if you are willing to put in a little work to keep your knife blade corrosion-free and without rust. Carbon steel is easy to sharpen, very durable, tough, and has good edge retention. Really it is a great steel that many of the best survival experts and outdoorsmen use because it checks off almost all of the boxes and is just a great survival knife steel.

The only major downside to carbon steel is its lack of corrosion resistance and the fact that you will need to spend a little bit of time to keep it in top condition. Other than that, it is a really solid and great survival knife blade option that is bound to serve you well.

| Benefits of Carbon Steel |

| Generally Cheaper |

| Easy to Sharpen |

| Good for Striking a Firesteel |

| Very Durable and Tough |

| Makes for a Great Survival Knife |

| Good Edge Retention |

| Drawbacks of Carbon Steel |

| Not Corrosion-Resistant |

| Needs Regular Maintenance |

Conclusion

When it comes to choosing the right survival knife blade steel, there is a lot to think about and choose. A lot of people overthink this process and end up getting a knife that has a steel that is not the best suited for them and their needs.

Make sure to really take your time when choosing a survival knife blade steen and evaluate what you really want out of the steel. Find what you value and what makes the biggest difference in the performance of a survival knife blade for you. Every person is different and values different aspects of knife blades.

Take it slow and really look at the available options. As well as choosing the right blade steel, pay a little extra attention to the other aspects of a survival knife blade. Namely, the heat treatment, blade coatings, and blade finishes.

It can seem overwhelming at times, but you can always try again the next time that you buy a knife and you will know more about what you prefer and like. The more knives you try and use for survival, the more you will know exactly what you want out of a survival knife blade.